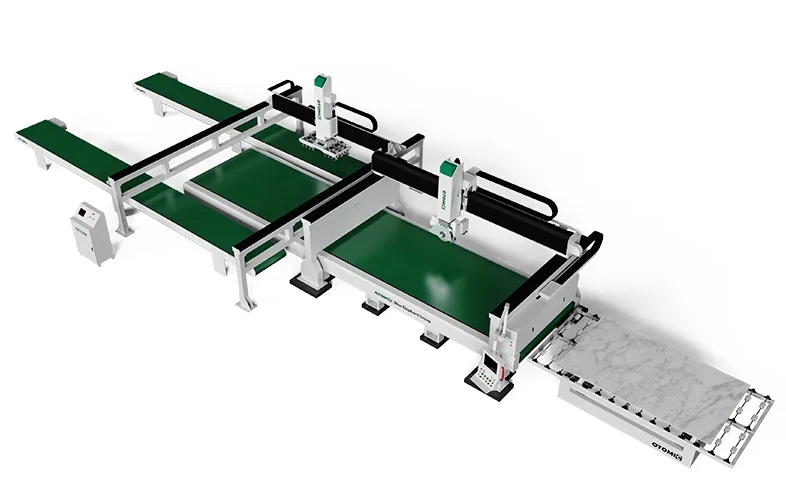

Multi-functional CNC 5 Axis Bridge Saw Machine Quarts Plate Production Line for Cutting and Polishing Stone

Function & Size: Made to your project's requirements

Payment: T/T, Visa, Master Card, American Express, etc.

Service: Operation, Installation, Maintenance Training

Supply ability: 200 Sets per month

STONE CNC MACHINING CENTER VIDEO

Description

The quartz stone cutting production line first developed by Blue Elephant CNC is designed to help customers process various stone products, such as quartz stone, marble and granite, etc. Its diverse functions can cut, polish, edge, drill, etc. . The 5 axis CNC bridge saw quartz stone cutting production line consists of three parts: a loading machine, an unloading machine and a 5 axis bridge saw machine. It is durable, budget-friendly, and has low maintenance costs. It is very suitable for large and small stone processing workshops.

Features

1.Diversified Functions

The quartz stone cutting production line has diversified functions and configurations, including camera function, tool setting function, thickness measurement function, suction cup function and milling cutter function. It saves time and manpower in operation, which greatly improves production efficiency.

2.Production Process Automation

The large stone slabs are placed on the processing line through a fully automatic loading machine, and are transported to the belt-type five-axis bridge cutting machine by the transition frame. The five-axis bridge cutting system automatically retrieves the cutting plan for the large slabs, and the system automatically adjusts the knife with AI, The plate is moved, the cutting is completed automatically, and then it is transported to the belt buffering position, and the plate is removed as needed.

3.Clear Division of Labor

Place the large stone slab on the fully automatic stone loading machine, and the stone slab is transported to the 5 axis bridge saw machine to realize automatic stone loading. The five axis bridge cutting machine cuts according to the preset engineering software. The automatic stone unloading machine can distribute stones to designated wire racks or palletizing racks according to the process. The cooperation of the three machines greatly improves work efficiency.

Parameters

| QX3400-5X-SP Quartz Stone Cutting Line | |||

| Bridge Saw | Working travel | X, Y, and Z | 3400*2000*250mm |

| C axis | ±365° | ||

| A axis | 0-90° | ||

| Maximum thickness | 80mm | ||

| Moving speed | 25m/min | ||

| Spindle | 22kw water cooling spindle, 4000rpm | ||

| Control system | CutCam | ||

| Motor | CutCam servo | ||

| Reducer | Japan SHIMPO | ||

| Worktable (optional) | Max. weight for feeding | 1500kg | |

| Max. speed for feeding | 10m/min | ||

| Saw | Dimension | 450mm | |

| Size | 6000×3500×3600mm | ||

| Loader | Working travel | X, Y, and Z | 3500*4000*1000mm |

| A axis | 0-90° | ||

| Control system | CutCam | ||

| Motor | CutCam servo | ||

| Reducer | Japan SHIMPO | ||

| Moving speed | 25m/min | ||

| Max suction size | 3200×1200mm | ||

| Min suction size | 300×150mm | ||

| Power | 8kw | ||

| Weight | 3000kg | ||

| Machine size | 5000×5800×3800mm | ||

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible